What’s the PLA+ and what’s the difference between PLA and PLA+?

If you are interested in 3D Printing, you must have an experience with PLA, and right now you are curious, as to why you should be interested in PLA+, or what’s the difference between standard PLA and PLA+.

Let’s read the following blog to find an answer what’s the difference. We are going to compare these two materials based on practical examples.

Start with the Technical side

The material itself is produced on the same basis, it is Polylactic Acid, which consists of natural starch. The rest is, of course, part of our trade secret.

The base of PLA and PLA+ is the same material, so it means, some of the properties are the same for both materials. Eg. Both materials have the same thermal resistance and they are both perfect materials for 3D Printing. If you are looking for a material with higher thermal resistance, we definitely recommend thinking about PETG, or industry filament than PLA.

So what does it mean for you?

Let’s start with the filament comparison

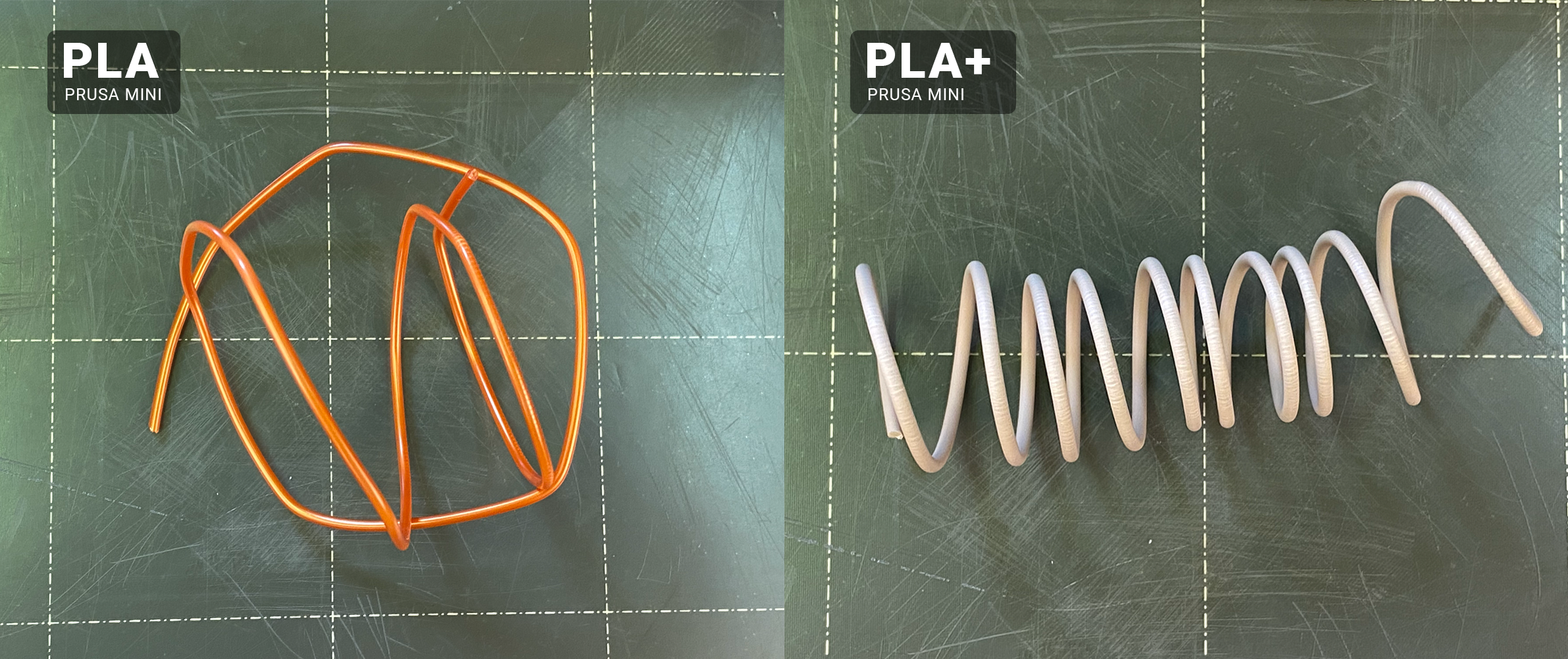

You can see the difference for the first time, you take the spool of PLA and PLA+. PLA looks more plastic it’s shiny and glossy. PLA+ has a more rough surface, it’s also due to the matte color. So it gives you the impression of more luxury and more extraordinary filament. The next difference is visible when you try to bend the filament. Standard PLA is very fragile and it breaks easily. On the other hand, there is no problem with PLA+ when you bend it ( of course, it breaks also, but at a certain point).

Matte color and untraditional shades

Matte color is one of the indications of this material. You know it – the matte color car looks simply better! It’s the same for PLA+. PLA+ is a new material, which is full of energy and very playful – when we choose other colors, it is very important for us to bring the most interesting and the least hackneyed shades. We offer the standard shades as White, Black, and Silver, as well as the special edition of Pastel colors or ARMY edition. RePLA+ is another new filament made from recycled PLA+ - more about RePLA+ you find here.

Filament loading

When you load a filament, you can see during the extrusion, that the molten PLA+ filament has a slightly denser consistency and it looks more complete, when it goes out from the nozzle. Of course, this is important for the next Printing properties.

First layer

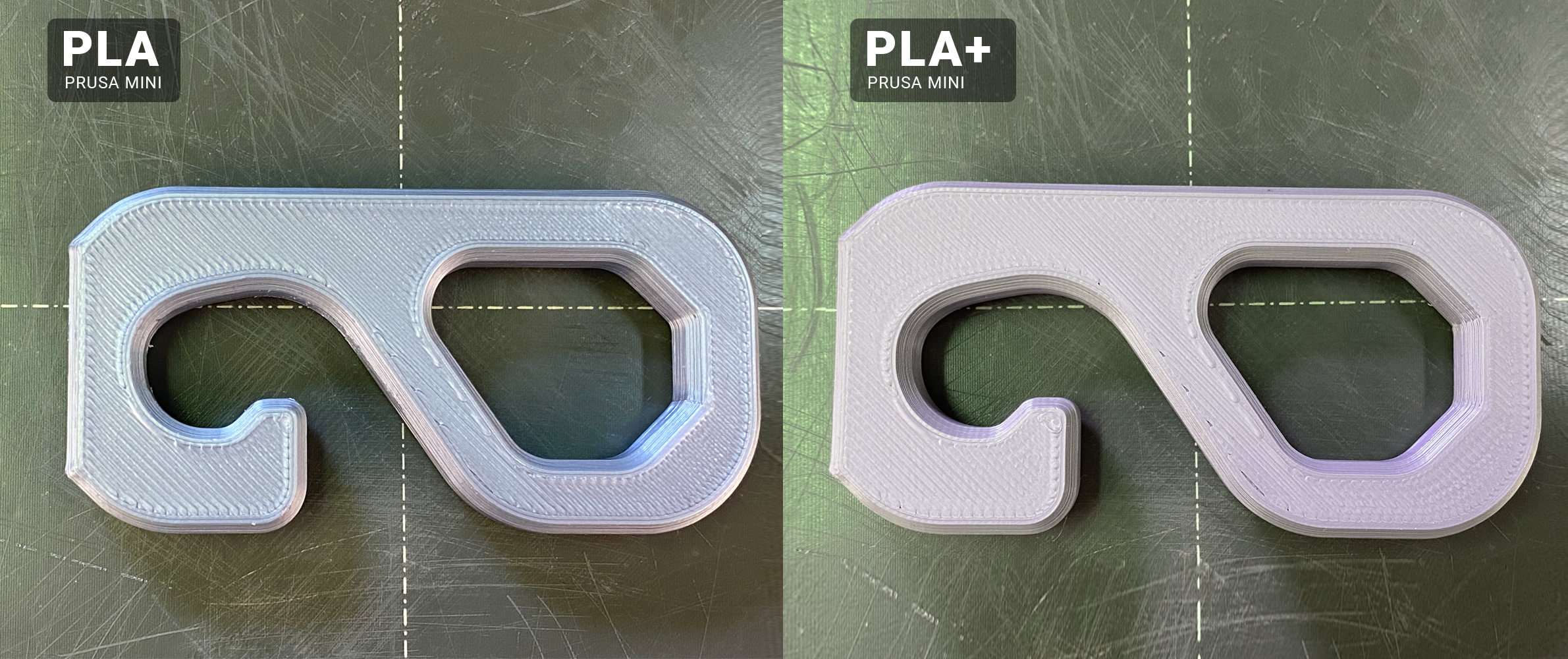

The first layer has never ever been easier. Because of its consistency, PLA+ has better bed adhesion, single layers are better connected and the surface looks more seamless.

You can see this when you are taking the 3D Printed object off the bed, PLA+ needs to be more peel off the bed because it’s tougher and it tends to copy the bed. If you check the lower side of the printed object, the PLA+ printed structure is almost non-recognizable and the surface is perfectly smooth ( even more when you use a PEI sheet).

The Layers

PLA+ - The printing properties of the first layer are the same for the whole printed object. We can say that ironing is the past. Thanks to PLA+, with the same Printing setting as for standard PLA, we are able to achieve a perfect smooth upper side without useless breaks. In comparison with Ironing, the PLA+ Printed object looks more natural and the overall impression is better.

And the result?

Right now is the time, to sum up, what we have learned. If we take into consideration all mentioned properties, PLA+ is a very suitable material for those, who would like to achieve perfect results, even for beginners. No complicated setting and calibration, but still we are able to get better results than with the standard PLA.

What we need to mention is that if you would like to post-process, the standard PLA is not suitable material for that. PLA+ is thanks to its matte appearance and Printing properties better for that – you can use emery paper or scalpel without any radical disruption of the object surface.

The quality

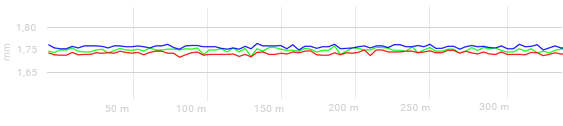

Yes, we do have new material PLA+, but it doesn’t mean that we reject our standard PLA. We are working on the top quality for both materials. We state the 0,05mm tolerance, which is expected for the top-quality filament. But the real numbers in production are even better – the tolerance is in fact around 0,03mm. So if you put emphasis on quality, both materials are a good choice. It’s up to you if you are more interested in matte colors, recycling (new RePLA+), Printing advantages, or if you stay loyal to standard PLA with more than 30 colors in our offer. Finally, it is up to your personal experience every time.